Cut to size at customers' need !

Add to Product FavoritesJS series Twin Shaft Concrete Mixer istwin horizontal shafts forced mixer. Combining advantages of single unit stand-alone operation and simple concrete batching plant with PLD series batching machine, the unit can work in concrete mixing station for prefabricated-component factories of various sizes and construction of highway, bridge, water, conservation and dock, etc. It can mix no-slump concrete, plastic concrete, fluid concrete, lightweight aggregate concrete and various mortar, as a widely used high efficiency model.

Twin Shaft Concrete Mixer worm gearing offers maximum operational reliability and a long service life – even when exposed to extreme loads. The gearboxes are directly mounted on the mixing shafts without a rigid connection to the mixing trough. With the selected material pairing, BHS Twin Shaft Concrete Mixer worm gearing compensates the load changes that occur every time the mixer is charged.

| Model | JS1000 | JS1500 | JS2000 | JS3000 |

| Discharge volume | 1000L | 1500L | 2000L | 3000L |

| Charging volume | 1600L | 2400L | 3200L | 4800L |

| Theoretical capacity | ≥60m³ | ≥90m³ | ≥120m³ | ≥180m³ |

| Aggregate sizes | ≤60/80mm | ≤80/100mm | ≤80/100mm | ≤80/120mm |

| Working circle | 60s | 60s | 60s | 60s |

| Mixing speed | 24.5r/min | 24.5r/min | 24.5r/min | 21r/min |

| Mixing arm quantity | 2×6 | 2×6 | 2×8 | 2×10 |

| Mixing motor model | Y25M-4 | Y280M-6 | Y280M-6 | Y315S-6 |

| Mixing motor power | 2×18.5 kW | 2×30 kW | 2×37 kW | 2×55 kW |

| Dimension (mm) | 3000×2200×2020 | 3000×2400×2074 | 3000×2400×2150 | 3000×2680×2450 |

| Overall weight (kg) | 5500 | 6500 | 7500 | 9200 |

Features

Features

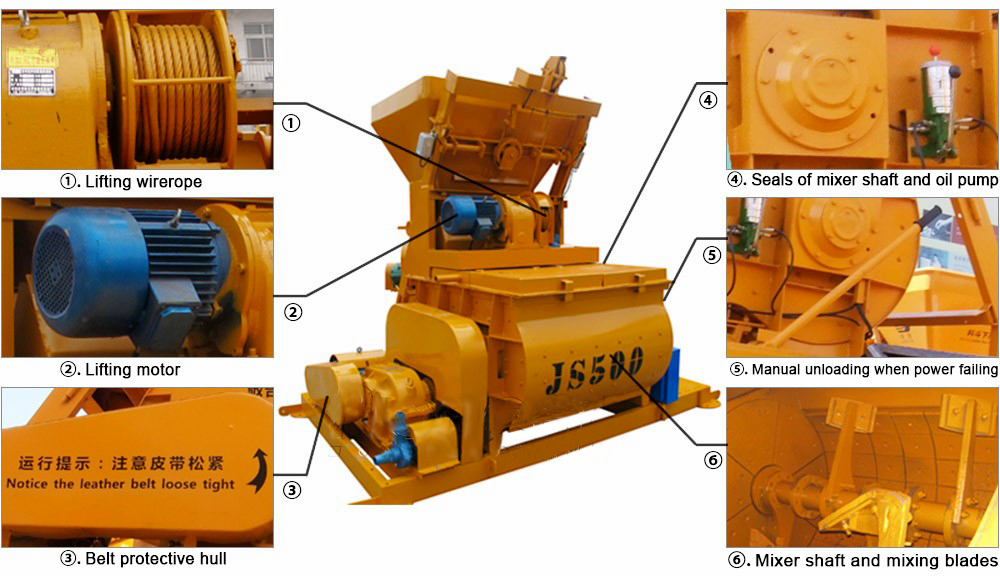

1. Mixing shafts are sealed with reliable axial face seals. The shaft bearings are mounted on bearing boxes and located separately from the shaft seals. This significantly increases operational reliability of the mixing shaft bearings.

2. A low-maintenance elastic coupling is installed between the gearboxes to synchronize the two mixing shafts.

3. High quality hexagonal shaft with high torsional and flexural strength

4. Streamlined mixing arms made of special cast steel, easily adjustable mixing blades

5. Rhombus-shaped tiles made of optimized cast chromium steel with a material thickness of 19mm can be used to line the mixing trough. The service life can be increased by up to 30% compared to tiles of rectangular design.

This concrete mixer can be used to mix stiff-consistency concrete, semi-stiff-consistency concrete, light weight aggregate concrete and so on.Features of JS500 Concrete Mixers:

1. As a miniature double-horizontal-shaft forced type concrete mixer, this concrete mixing machine features short mixing time, good homogeneity and reliable operation.

2. Shaft tip is sealed by floating-ring, which is reliable and easy to maintain and replace.

They are widely used to produce dry hard concrete, plastic concrete, flow concrete, light aggregate concrete, various mortars, etc. Suitable for all kinds of big, medium and small precast concrete plant;

1. Standard seaworthy container 20 GP or 40 GP ,40 HQ according to configuration ;

2. With wires for fastening the machine and frame structure inside the container ;

3. The electric items and installation components packed with strong and standard packages.

Product Lists

breif introduction of us

Haomei Machinery

Haomei Machinery

Haomei Machinery

WhatsApp / Webchat

+86 135 9841 7520

News Lists

Case Lists

Haomei Machinery

Haomei Machinery

WhatsApp / Viber

+86 135 984 17520

Haomei Mixing Plant

+86 (0)371-65621391